Home > Building a Resilient Global Sourcing Strategy as a UK SME

For UK SMEs, sourcing globally is no longer a side project — it’s how you stay competitive. Overseas suppliers offer cost savings, new products, and faster scaling. But behind every low unit price lies a network of risks: currency swings, long lead times, and hidden payment fees that quietly eat into margins.

This guide helps UK importers and e-commerce firms build a sourcing strategy that lasts — one that balances cost with control, and growth with resilience.

1. Why Global Sourcing Still Matters

When executed well, a global sourcing strategy does more than cut costs. It strengthens your entire business model.

Lower costs, higher margins. Manufacturing abroad gives access to affordable, high-quality production — often at a fraction of domestic prices.

Unique products. Access to exclusive materials or specialist manufacturers helps UK businesses stand out in competitive markets.

Stronger resilience. A diversified supply chain offers protection against inflation, trade disruption and local shocks.

But sourcing isn’t about chasing the cheapest quote. It’s about building a dependable network that supports your brand for the long term.

2. The “China +1” Era

For two decades, China has been the backbone of global manufacturing — and for good reason. Its scale, infrastructure and production expertise remain unmatched. Even as supply chains diversify, most UK SMEs still depend on China for part of their sourcing network. The country’s dominance in electronics, textiles, machinery and components means that even products assembled elsewhere often rely on Chinese inputs somewhere along the line.

Rising costs, shifting geopolitics and stricter compliance standards have led many businesses to adopt a “China +1” strategy — keeping their established Chinese suppliers while adding at least one alternative production base elsewhere. This approach balances risk without losing access to China’s supply-chain efficiency and deep manufacturing networks.

2.1 Why China Still Matters

Despite diversification, China remains critical for three main reasons:

- Unmatched supply chain depth. No other country offers the same integration of component makers, logistics providers and export infrastructure. Shenzhen alone can produce a prototype in days — a speed difficult to replicate elsewhere.

- Skilled labour and quality consistency. Chinese factories have decades of experience serving global brands, meaning tighter quality control, strong production management and reliable delivery timelines.

- Infrastructure and efficiency. With world-class ports, logistics networks and manufacturing clusters, China still delivers the lowest landed cost for many categories — particularly electronics, machinery and consumer goods.

2.2 Looking Beyond China

Still, dependency carries risk. Costs are rising, and trade tensions can disrupt supply lines overnight. That’s why UK SMEs are increasingly adding secondary hubs in Vietnam, Malaysia, Indonesia and India, or shifting part of their production closer to home in Eastern Europe or Latin America.

Diversification doesn’t mean abandoning China — it means building flexibility. The most resilient sourcing strategies use China as an anchor while developing alternatives that can scale when conditions change.

3. How to Build Reliable Supplier Partnerships

Finding a manufacturer is easy. Finding one you can trust is not. Follow these steps to build lasting partnerships that protect your business.

3.1 Define Exactly What You Need

Create a product specification sheet covering every detail — dimensions, materials, colours, packaging and testing standards. Use it across all suppliers so you can compare quotes fairly and avoid costly miscommunication.

3.2 Vet and Shortlist Suppliers

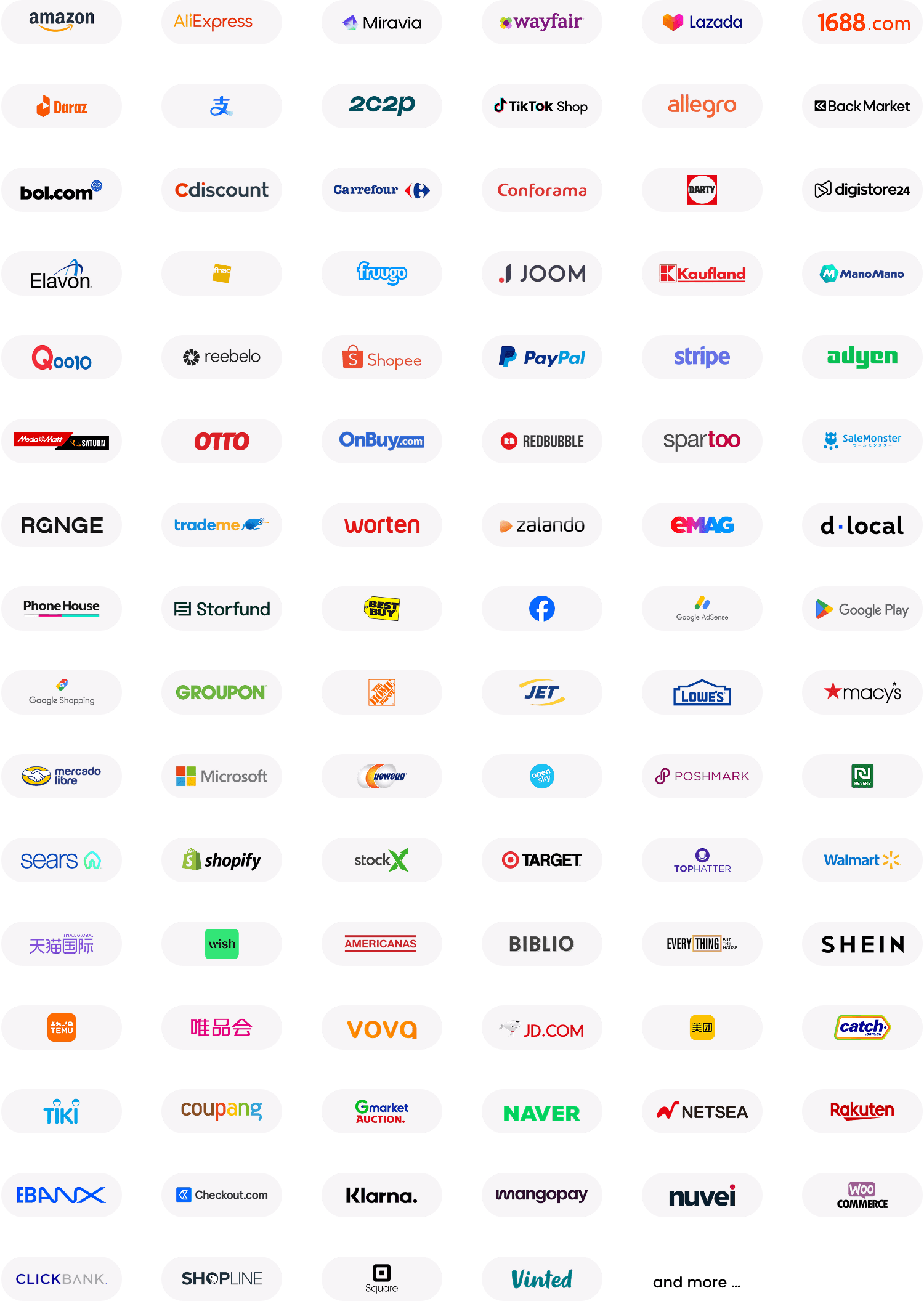

Platforms like Alibaba are useful starting points, but filters matter. Focus on Verified and Trade Assurance suppliers — checks that confirm legitimacy and protect your payments. Narrow long lists to a small pool of credible factories that meet your standards.

3.3 Test Responsiveness

A supplier’s communication tells you more than a quote ever will. Reliable partners:

- Reply within 48 hours

- Provide clear, specific answers

- Are open to video calls and documentation

- Send photos, specs or timelines without prompting

If communication feels vague or defensive now, it won’t improve later.

3.4 Order and Test Samples

Samples are your first line of defence. If you’re sourcing sleeping bags — test them outdoors. If you’re buying ceramics — use them daily. You’re not testing perfection, but consistency and honesty.

3.5 Insist on Independent Quality Checks

Book a third-party quality control inspection before shipment. If it fails, request a re-inspection at the factory’s cost. Minor surface issues can be corrected; structural ones cannot. Add this clause to your purchase order to protect your position.

4. Calculating the True Cost of Imports

A supplier’s quote is only the beginning. To see the real margin, calculate your landed cost — the total price of getting a product from factory floor to warehouse shelf.

4.1 What Your Landed Cost Includes

- Unit price: What you pay the factory.

- Freight: Air or sea shipping, including insurance.

- Tariffs and duties: Determined by HS codes and product origin; a small misclassification can cost thousands.

- Local logistics: Delivery from UK port to warehouse.

- Payment and FX fees: Often ignored — but can take 2–4% off every order.

A £50,000 shipment misclassified under the wrong HS code could cost an extra £3,000 in duties. Add hidden FX losses, and your savings evaporate.

5. The Hidden Cost of Paying Overseas

Over 70% of UK SMEs still use their high-street bank for international transfers — and overpay for the convenience.

5.1 Where the Money Disappears

Traditional banks charge twice: a small transfer fee, and a much larger hidden margin on the exchange rate — the gap between their offered rate and the real mid-market rate.

A 2024 Wise and Censuswide report estimates UK SMEs lost between £2.2 and £2.8 billion in hidden FX costs last year.

While big banks charge margins of around 3–4%, specialist providers like WorldFirst cap rates at 0.6% — helping SMEs keep more of their revenue.

High banking costs remain one of the biggest barriers to global expansion, discouraging one in four UK firms from entering new markets.

6. Smarter Ways to Manage Global Payments

Modern fintech platforms offer faster, cheaper and more transparent payment solutions built for SMEs.

6.1 Use a Multi-Currency Account

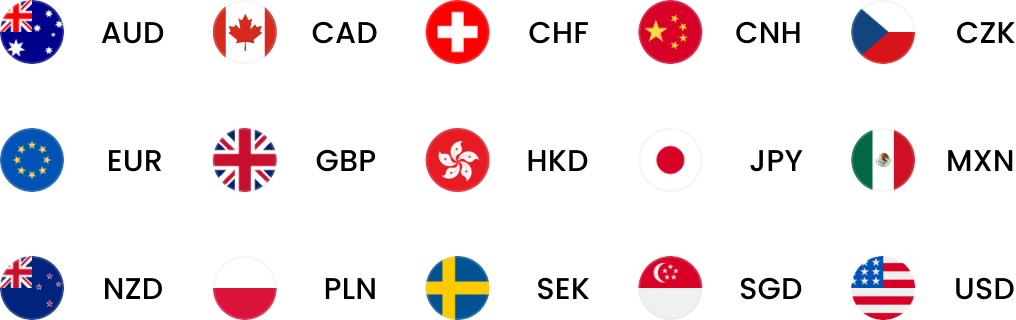

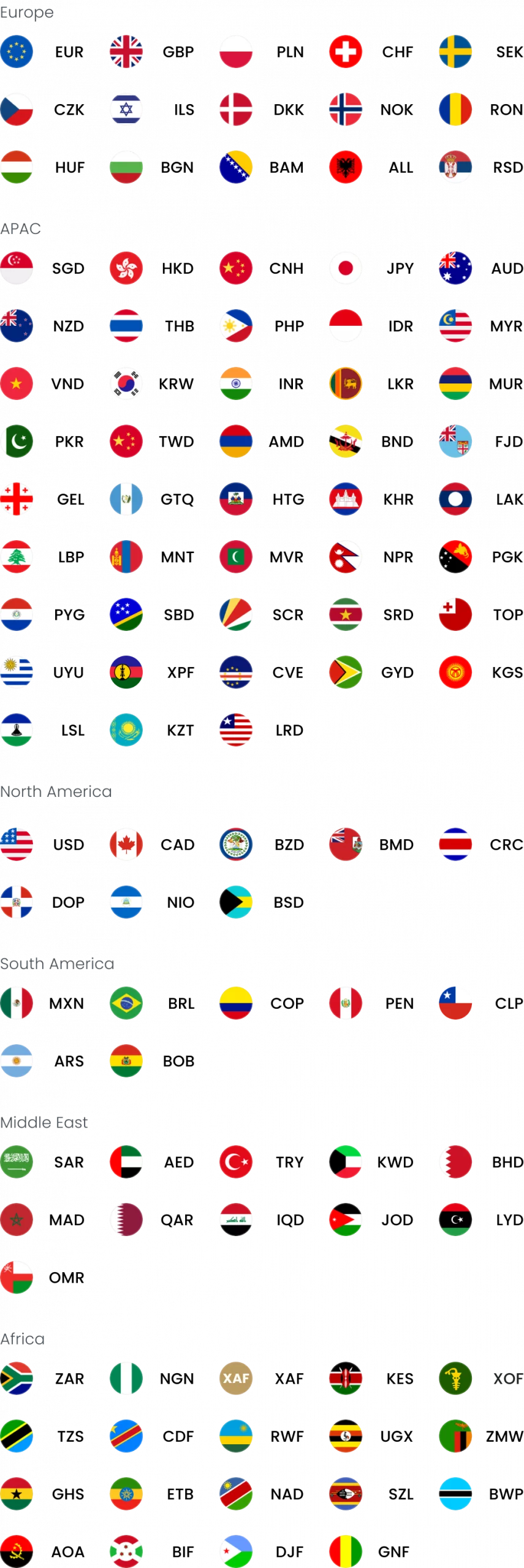

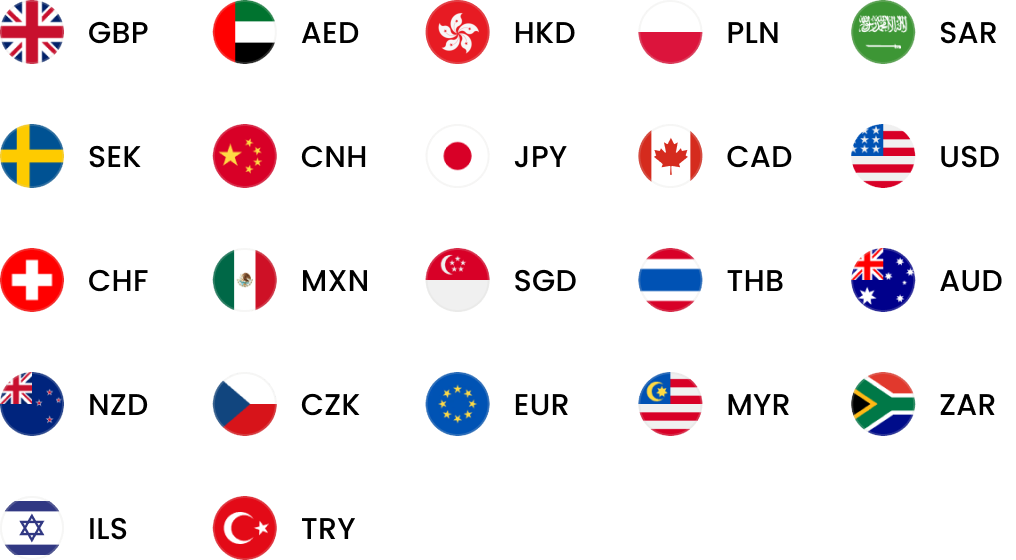

A multi-currency account, such as the World Account, lets you hold and pay in multiple currencies without opening foreign bank accounts. Paying suppliers in their local currency avoids forced conversions and reduces FX costs.

6.2 Pay Like a Local

Paying a supplier in CNH, EUR or USD builds trust and speeds up reconciliation. It shows professionalism and ensures both sides know when payments clear.

6.3 Integrate and Automate

Connecting your payment platform to accounting tools like Xero simplifies reconciliation and reduces manual work. Instant notifications also reassure suppliers that funds have landed.

6.4 Hedge Against Volatility

FX forward contracts let you lock in an exchange rate for future payments. This gives you certainty over costs and protects margins from currency swings.

7. Managing Lead Times and Logistics

7.1 Plan Ahead

Allow about 100 days from order to delivery — roughly two months for production and one for shipping. Add buffer time around holidays like Chinese New Year, when factories close for weeks.

7.2 Avoid Common Pitfalls

- Measure packaged dimensions for accurate freight pricing

- Account for dimensional weight in shipping estimates

- Budget for storage during peak seasons

- Have a plan for returns or unsold inventory

Small oversights can turn profitable imports into expensive lessons.

8. Build for the Future

A resilient sourcing strategy balances cost, quality and flexibility. Diversify suppliers, strengthen relationships, and manage payments with precision.

Modern tools like the World Account help UK businesses reduce FX costs, streamline operations and pay suppliers faster — giving SMEs the confidence to trade globally on their own terms.

Start by mapping your supply chain and identifying where money leaks. The more control you take, the stronger your business becomes.

Jennifer Dodd leads marketing for WorldFirst UK, and has over 20 years' experience in financial services and publishing.

Jennifer Dodd

Author

Continue reading

Subscribe

The Weekly Dispatch

Get the latest news and event invites. Signup for our weekly update from the worlds of fashion, design, and tech.

You might also like

Choose a product or service to find out more

E-commerce guides

Doing business with China

Exploring new markets

Business Tips

International transactions

E-commerce expansion guides