How to manage quality control in China

Last updated: 23 Jun 2025

Learn how to effectively manage quality control when sourcing products from China to ensure consistency and avoid costly defects

Key takeaways

- Quality control ensures consistent product standards, reducing defects, customer complaints and costly product returns

- Collaborating with reliable suppliers and conducting regular audits are key to maintaining high product quality when sourcing from China

- Clearly defined quality control plans—for products, processes and new developments—set clear expectations for manufacturers

- Pre-production, during-production and pre-shipment inspections help catch issues early and ensure quality is maintained at every stage.

Maintaining consistent product quality is a major concern for businesses sourcing products from China. While you can ask for product samples before placing a large order, ensuring the same quality is maintained across all the products that get delivered can be challenging.

As the importer, it’s your responsibility to set up and manage quality control processes, not the manufacturer’s. Returning defective or low-quality products can be time-consuming, costly and complicated.

But, introducing quality control is much more than just visiting the factory once and meeting the manufacturers face-to-face. It’s about establishing consistent processes that are followed throughout the supply chain.

In this blog, we discuss the importance of quality control and how you can effectively manage quality control with your manufacturers in China.

Table of Contents

Importance of quality control

Quality control is the process of ensuring your manufactured products adhere to the defined set of quality criteria or meet the requirements of the end customers. It involves strategic testing, inspection and verification of products.

A streamlined quality control process is important for numerous reasons, including:

Consistent product quality verification: It ensures that every product you receive from manufacturers adheres to the required quality standards.

Fewer changes or variations: Regular quality control checks ensure consistency across different product batches and decrease variations.

Reduced losses due to product defects: Quality control makes it possible to quickly identify and address any defects early on, reducing the number of defective products you receive. This directly helps avoid costly recalls and customer disappointment.

Improved customer retention: When you offer your customers high-quality products every time, they are bound to return and make repurchases.

Quality control strategies: Steps to manage quality control in China

Here are the steps you can take to implement effective quality control measures in China:

1. Clearly define your quality requirements

You need to be upfront about your quality requirements with the manufacturers, including the product specifications, maximum acceptable tolerance and any other specific testing requirements that you might have.

2. Choose experienced suppliers

The easiest way to ensure you get high-quality products is by partnering with reputable and reliable suppliers with experience in producing high-quality products. Before you finalize a supplier and place a large order, conduct in-depth supplier audits to assess the product quality, factory product capabilities and quality control measures.

You can also use a third-party inspection agency to conduct random or unannounced audits to get unbiased feedback on the supplier’s capabilities.

3. Build a detailed quality control plan

Your quality control plan should clearly outline the testing procedures, points of inspection in the manufacturing process and the acceptance criteria for different checkpoints.

Here are the three different types of quality control plans that you should consider building:

Product QC plan: The plan should include your expectations for production capabilities, product qualities and timely inspection.

Process QC plan: The plan includes details about how the manufacturer is expected to address any issues that might arise.

New product QC plan: The plan can be used when getting a new product manufactured for the first time. It can help manufacturers understand your exact quality expectations and ensure the product is developed as per the timelines.

- Open 15+ local currency accounts and get paid like a local

- Pay suppliers, partners and staff worldwide in 100+ currencies

- Collect payments for free from 130+ marketplaces and payment gateways, including Amazon, Etsy, PayPal and Shopify

- Save with competitive exchange rates on currency conversions and transfers

- Lock in exchange rates for up to 24 months for cash flow certainty

4. Conduct all the necessary quality inspections

After sharing the QC plans with your manufacturer, the next step is to conduct all the necessary quality inspections.

Here are the different types of quality inspections that you should consider:

Pre-Production Inspection (PPI): It involves inspecting all the components and raw materials involved in manufacturing.

During Production Inspection (DUPRO): This quality inspection is conducted after 50% or more of the goods have already been manufactured. Quality inspectors visit the factory, select some of the manufactured units randomly and compare them against pre-discussed product specifications. The products are also checked for regulatory compliance.

Pre-Shipment Inspection (PSI): Also known as Final Random Inspection (FRI), these tests are conducted when the production is 100% complete or at least 80% complete. It involves quality inspectors reviewing the products before they are packed and shipped. At the final stage, you need to check products for any major or minor defects.

5. Collaborate with manufacturers for continuous improvement

While sharing your quality expectations upfront is important, you also need to share timely feedback on any quality issues you have identified. A quality control process can only be successful when businesses collaborate closely with manufacturers and address any concerns early on.

Even after the first batch of products is delivered, identify areas of improvement and implement corrective measures for the same.

Who can conduct quality control in China on your behalf?

Third-party inspection agencies: There are dedicated agencies that help businesses with end-to-end quality inspection, which includes random factory audits, production monitoring, pre-shipment inspections and product testing.

Sourcing agents: When you partner with sourcing agents, they help you manage the entire sourcing process–from searching for reliable manufacturers to communicating your product requirements and conducting routine quality checks. They can also help you streamline documentation for customs clearance.

Certification authorities: There are also Chinese certification agencies that perform rigorous quality tests on products to ensure the products are compliant, safe and environmentally friendly.

Pay suppliers in China at competitive exchange rates

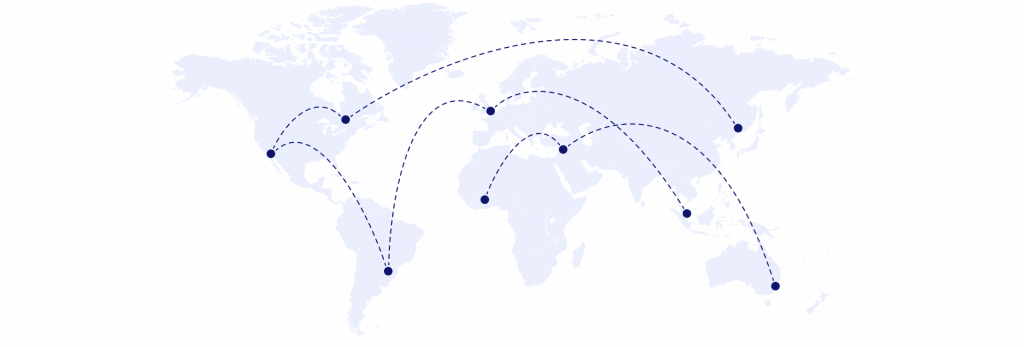

SMEs and online sellers can open a World Account in minutes and pay suppliers in China like they are just around the corner.

One World Account lets you set up virtual local currency accounts in 15+ currencies, including GBP, USD, CAD, EUR, AUD, NZD and CNH. Local currency accounts are created under your business’s name. For every currency, you get a separate account number and branch code.

You can send payments to suppliers in 40+ currencies and get access to interbank/ mid-market exchange rates.

Disclaimer: The information contained is general only and largely our views. Before acting on the information you should consider whether it is appropriate for you, in light of your objectives, financial situation or needs. Although information has been obtained from and is based upon multiple sources the author believes to be reliable, we do not guarantee its accuracy and it may be incomplete or condensed. All opinions, estimates, mentioned products/services and referenced material constitute the author’s own judgement as of the date of the briefing and are subject to change without notice. WorldFirst shall not be responsible for any losses or damages arising from your reliance of such information.

1688 vs Alibaba: Which is better?

Between 1688 and Alibaba, which is the better B2B marketplace for sourcing products? Let’s find out.

Oct / 2025

How to use Alipay as a foreigner (Both in & outside China)

Learn how to use Alipay as a foreigner for seamless payments in China. Link a World Card to your Alipay account to make seamless and secure transactions.

Oct / 2025

Canton Fair 2025: Your guide to the China Import and Export Fair

The Canton Trade Fair is one of the world’s biggest exhibitions that connects sellers and buyers.

Oct / 2025Insights from WorldFirst cover the latest FX news, top accounting tips, strategies to mitigate risk and key industry trends. Choose a category below to find out more.

- Almost 1,500,000 businesses have sent US$500B+ around the world with WorldFirst and its partner brands since 2004

- Your money is safeguarded with leading financial institutions