From RFQ to delivery: How to protect your margins as an Amazon seller

Last updated: 19 Nov 2025

Stop losing profit to poor sourcing practices. Learn how to manage every stage, from Request for Quotation (RFQ) to delivery, and protect your margins with WorldFirst

Key takeaways

- Effective sourcing means managing every stage, not just unit costs

- Write clear, detailed RFQs to attract reliable suppliers and fair quotes

- Document all agreed terms to avoid disputes and production delays

- Pay suppliers in their local currency via World Account – all at competitive exchange rates

- Use inspections and checkpoints to maintain product quality and delivery timelines

Most Amazon sellers put all their focus on driving down unit costs of their products when their real margins get eaten up by unclear RFQs, missed deadlines, poor quality checks and delayed shipments.

If you’ve ever paid for express air freight because production ran late or you received a batch of defective products with no time left to fix them, you know what that means.

Effective sourcing is about managing each stage of the supplier relationship to protect margin, product quality and time-to-market.

This guide walks through a proven sourcing workflow, from RFQ to delivery.

Table of Contents

1. Getting the RFQ right

Don’t just use RFQs (Request for Quotations) to get the lowest price. Instead, you should use them to build long-term partnerships with suppliers that help you protect your margins, ensure consistent quality and support business growth.

Your RFQs should include comprehensive information about:

- Product specifications (dimensions, materials, functionality, tolerances)

Packaging and labeling requirements (especially for Amazon FBA compliance) - Delivery timelines

- Minimum order quantities and expected reorder volumes

Over-negotiating and pushing too hard on cost, especially when dealing with overseas suppliers, where language barriers and cultural differences may already complicate communication, can impact supplier relationships even before a deal is made.

Instead, be more transparent and upfront with suppliers. Clearly outline your payment terms, collaboration timelines (such as product revisions or scale-up plans) and your intended process for future orders.

Make it easy for suppliers to respond to your RFQs by being specific without overcomplicating things. Use plain, structured language and stick to clear formatting; alternatively, share your RFQ templates. Investing a little more effort upfront can save you from endless back-and-forths later.

2. Confirming terms clearly

Once you’ve found a supplier you want to move forward with, the next step is to lock in the terms and document everything properly. You don’t want to be relying on a long thread of emails or WeChat messages to ‘prove’ what was agreed.

Compile everything into a document and make sure it includes all the information you have aligned with the supplier, such as:

- Final unit price

- Production lead time (For the different stages of the production)

- Quality control (QC) process (Who handles inspections and at what stages?)

- Payment milestones

- Shipping method (How will the suppliers ship the goods or do you need a shipping agent for it?)

When your supplier knows you’re organised and serious, they’re more likely to prioritise your order and flag issues early if something goes off track.

3. Getting payments right

The way you set up payments can make or break your supplier relationship and even your margins. Yes pricing is not the only thing that matters when dealing with suppliers, but setting your payment terms and processes right from the start is incredibly important.

Payment terms to decide and discuss early

When will payments be made?

While the payment terms can differ for each supplier, product category and industry, here are some common payment milestones you can consider:

- 30% upfront, 70% after production (30/70)

- 50% upfront, 50% on shipment (50/50)

- Full payment after inspection (less common and harder to negotiate with new suppliers)

How much to pay at each stage?

Your upfront deposit should be enough to secure raw materials, but not so much that you’re exposed if things go wrong.

What currency does your supplier prefer?

This is often overlooked, but the currency you’re paying in can also directly impact your profit margins due to market fluctuations. If you insist on paying in AUD or NZD, your supplier will likely pad their pricing to cover FX risks.

In most cases, suppliers will calculate pricing based on the FX rate at the time of invoicing, but they’ll also factor in the risk of currency fluctuations and add a buffer to cover any transaction fees they might be charged. As a result, the FX rate you end up paying may almost never be in your favour.

Additionally, this FX rate and fee combination will change each time you make a payment, based on daily market fluctuations. That makes it extremely difficult to forecast your landed costs and protect your profit margins.

Pay your suppliers like a local with WorldFirst

Paying in your supplier’s local currency (like CNY for Chinese vendors) means fixed pricing from suppliers, fewer hidden fees and stronger business relationships.

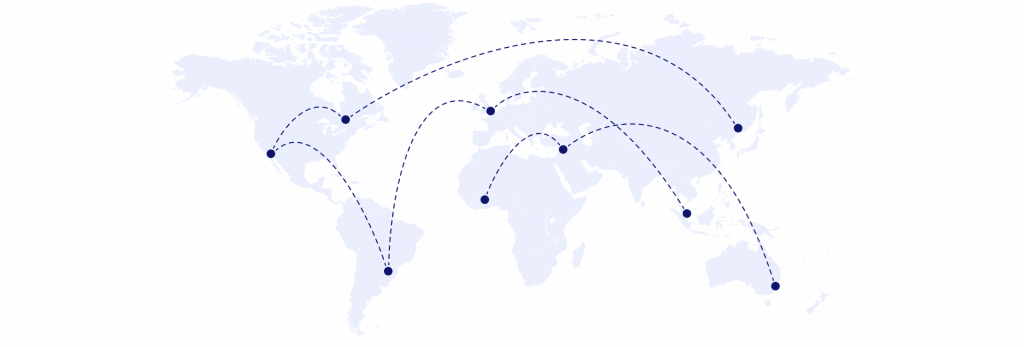

With a World Account, you can send payments in 100+ currencies, including same-day or next-day transfers (cut-off times apply). You also get local account details in 15+ major currencies like USD, CNH, EUR and GBP, allowing you to hold and receive payments like a local business without needing an overseas address.

Lock in exchange rates for up to 24 months to get more control over currency volatility and protect your profit margins. Managing your cash flow becomes easy as you can convert funds when rates are favourable and hold them until you’re ready to pay suppliers.

- Open 15+ local currency accounts and get paid like a local

- Pay suppliers, partners and staff worldwide in 100+ currencies

- Collect payments for free from 130+ marketplaces and payment gateways, including Amazon, Etsy, PayPal and Shopify

- Save with competitive exchange rates on currency conversions and transfers

- Lock in exchange rates for up to 24 months for cash flow certainty

4. Monitoring your production

Once you have paid in advance and your order is in process, you still need to monitor the production process which of course can be a bit challenging if your supplier is in a whole other country (or continent).

Here are a few tips to manage the production phase properly.

Check the pre-production sample carefully

Before your production scales up, ask the suppliers to send you a pre-production sample so that you can assess the quality of the products closely. You should test the material quality, dimensions, finish, packaging and any relevant functionality. Every unit that follows will be measured against this sample, so make sure to inspect it thoroughly.

If the sample isn’t 100% right, provide clear feedback and ask for a revised version. Asking the supplier to ship another version of the product will still cost you far less than dealing with an entire batch of flawed inventory.

Set up key production checkpoints

As the production scales, establish clear checkpoints throughout the production timeline.

Pre-Production Inspection (PPI)

Conducted before manufacturing begins, it checks raw materials, components and factory readiness.

During Production Inspection (DUPRO)

This inspection is conducted when ~50% of the goods are produced. It involves picking out random sample units at the factory and checking them against your specifications. It is critical to prevent late-stage surprises.

Pre-Shipment Inspection (PSI)

Also called Final Random Inspection (FRI), it is ideally performed when at least 80-100% of the order is complete. This is your last opportunity to catch issues before goods are packed.

Who can help you with quality control?

- Third-party inspection agencies

These agencies can perform factory audits, on-site quality checks and lab testing on your behalf and provide you with detailed reports. They’re ideal if you want a neutral party to inspect the goods. - Sourcing agents

A good agent can manage the whole process for you, right from finding manufacturers, negotiating terms, conducting spot checks, handling shipping and even helping with documentation and customs. - Certification authorities

If you’re dealing with regulated categories (toys, electronics, cosmetics), ask independent certification bodies to test the products for compliance and safety standards.

5. Managing delivery

You can either ask your supplier to handle shipping or work with a freight forwarder or logistics partner. Get shipping quotes well in advance, ideally before production begins, so you know exactly how much each shipment will cost. Compare multiple carriers and transit times.

Keep in mind: air freight may be faster, but it can cost 5-10 times more than sea freight. Unless you’re restocking a best-seller, rushed shipping often kills your margin, especially for low-cost or bulky items.

If you’ll be using Amazon FBA, consider working with an experienced Amazon FBA supplier who understands the platform’s packaging and labeling requirements. Amazon clearly states that non-compliant shipments may result in penalties, delays, or returned goods. Learn more about Amazon’s FBA product preparation requirements here.

Protect your margins with smart sourcing

You can’t control everything, but you can control a lot when sourcing. With an international payment provider like World Account, you can streamline payments and pay suppliers in local currencies–all at competitive exchange rates. Sourcing smart isn’t just about cutting costs; it’s about protecting your profit.

Disclaimer: The information contained is general only and largely our views. Before acting on the information you should consider whether it is appropriate for you, in light of your objectives, financial situation or needs. Although information has been obtained from and is based upon multiple sources the author believes to be reliable, we do not guarantee its accuracy and it may be incomplete or condensed. All opinions, estimates, mentioned products/services and referenced material constitute the author’s own judgement as of the date of the briefing and are subject to change without notice. WorldFirst shall not be responsible for any losses or damages arising from your reliance of such information.

How to find new suppliers for your Amazon business?

Find reliable Amazon suppliers beyond China. Discover new sourcing hubs, vet partners effectively, and pay globally with WorldFirst.

Nov / 2025

Mastering the inventory equation as an Amazon seller

Avoid stockouts, reduce storage costs, and optimise cash flow. Learn how to manage inventory and protect margins as an Amazon seller.

Nov / 2025

From RFQ to delivery: How to protect your margins as an Amazon seller

Protect your margins as an Amazon seller with smarter sourcing. Learn how to manage RFQs, payments, QC, and delivery efficiently.

Nov / 2025Insights from WorldFirst cover the latest FX news, top accounting tips, strategies to mitigate risk and key industry trends. Choose a category below to find out more.

- Almost 1,500,000 businesses have sent US$500B+ around the world with WorldFirst and its partner brands since 2004

- Your money is safeguarded with leading financial institutions